PRODUCT

WHAT WE DO

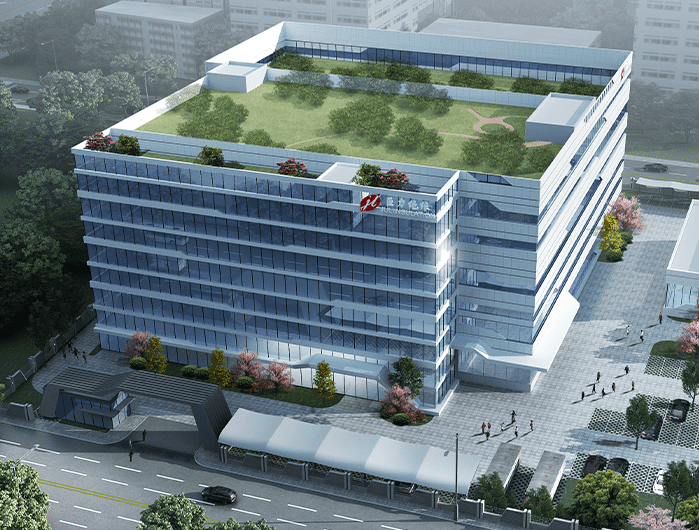

杭州巨力绝缘材料有限公司成立于2002年,注册资本6600万,公司专注于生产专业通讯电缆屏蔽用金属复合材料,致力于成为全球生产通讯电缆屏蔽材料以及各类复合材料的科技型企业,公司主要产品有热熔铝箔、单双面铝箔、润滑铝箔、热融PET膜、以及其他功能性铝箔屏蔽材料,广泛应用于高速线、汽车线、数据缆以及其他通讯线缆,依靠先进的技术和工艺,取得了光电线缆屏蔽领域的30余项专利技术,产品通过了IATF16949、ISO13485、AS9100,ISO9001、ISO14001体系认证,符合欧盟RoHS及REACH要求,产品远销国内外二十多个国家和地区。

注册资金

行业生产制造经验

拥有专利